ESVB12 - Hose Break System

Safety First

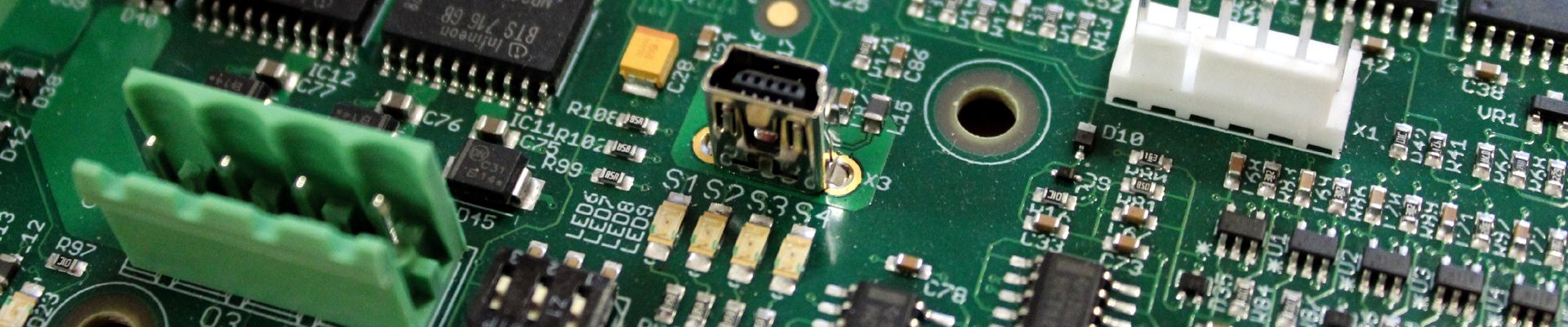

This hose break protection system is failsafe and it is the only system in the world which can test for proper functionality before using the machinery. This test can be performed from the cabin in a few seconds. One button checks the system’s response to a pipe fracture and another checks the operation of the pressure sensors.

Less environmental impact

A comparative test indicated that our system is better at preventing oil leakage in the event of a hose rupture or pipe break, compared to other systems on the market.

The ESVB system immediately stops the oil feed in the ruptured pipe or hose resulting in minimal oil leakage.

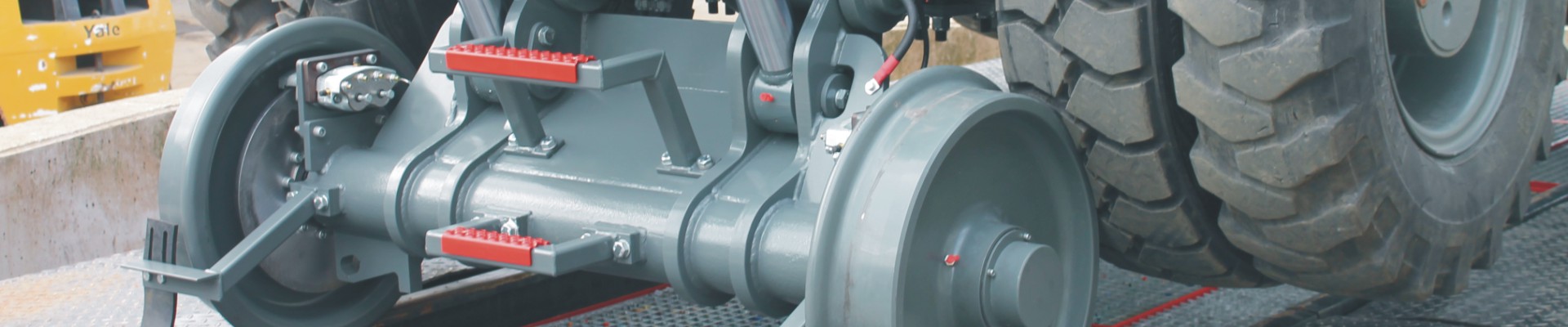

Compact

The ESVB electric/hydraulic valves are the most compact safety valves on the market. Even the 800 L/min capacity valves are no bigger than 170x100x100 mm.

They are often the only valves that can be fitted on wheel loaders due to their compact size.

Blocking the movement when a rupture occurs

In contrast to servo-controlled hose break valves, these valves completely stop the movement of the arm during a hose break. As well as stopping more oil loss it alerts the operator to a line failure. This is unlike a servo-controlled system where the operator is unaware of a hose break until the end of the lowering motion resulting in a large oil spill.

No effects on the operation

Because the valves on our system are fully open or closed, there is no impact on normal operation. Servo-controlled valves do not close exactly at the same time creating shuttering and torsion, which can cause long-term damage to wide framed wheel loaders.

The ESVB system does not produce any heat on the hydraulic system.

The ESVB system is patented in Europe, no. 0404271.

.png)

.jpg)