BE-AR RAIL SYSTEM

AUTOMATIC SLANTING CORRECTION

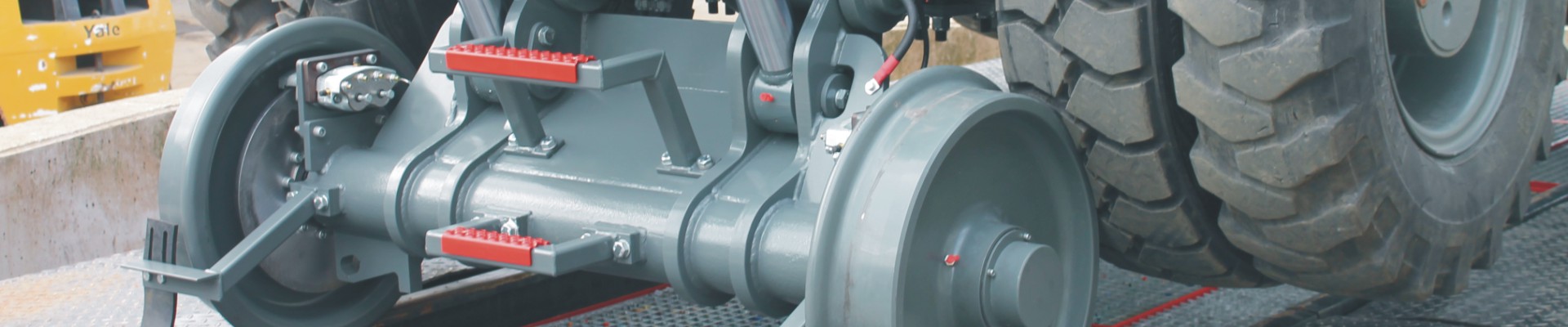

Rail guidance

The BE-AR rail system (a partnership between BErende Spoorwerken & Van ARkel of Nijhuis Engineering) is a patented invention, incorporating a unique rail-wheel guidance system, which is a simple levelling system and does not require a complicated control system. The parallel suspended rail-wheel set creates perfect rail guidance and also improved stability for the machine because the supports are as near as possible to the rail-wheels.

It enables the machine operator to do pick-and-carry work over the side and still remain stable as if working with the oscillating axle locked, which is forbidden.

The BE-AR system allows higher loads while still adhering to the EN-15746 standard.

Run high or run low

The hydraulic drives enable the BE-AR system to ride high on the rail-wheels or ride low on the rubber tires. The advantage of running high is less tire wear, and when running low increased traction.

Why use our BE-AR railsystem?

- Non-oscillating axle making it safer to use.

- Heavier mobile load charts within the EN-15746 limits.

- Can be fitted to all types of excavators.

- Easier to use for the operator due to one mobile load chart.

- More versatility meaning fewer machines on a project

- Fewer limitations resulting in cost savings.

- Complies with EN-15746 for safety, compatibility and rail use.

- Can be fitted on different machines for railroad-construction machines.