TM Hi-Rail modification

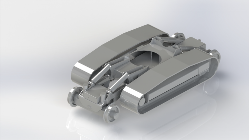

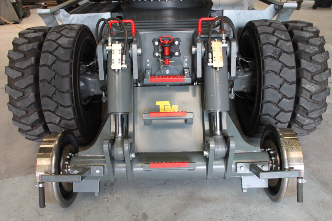

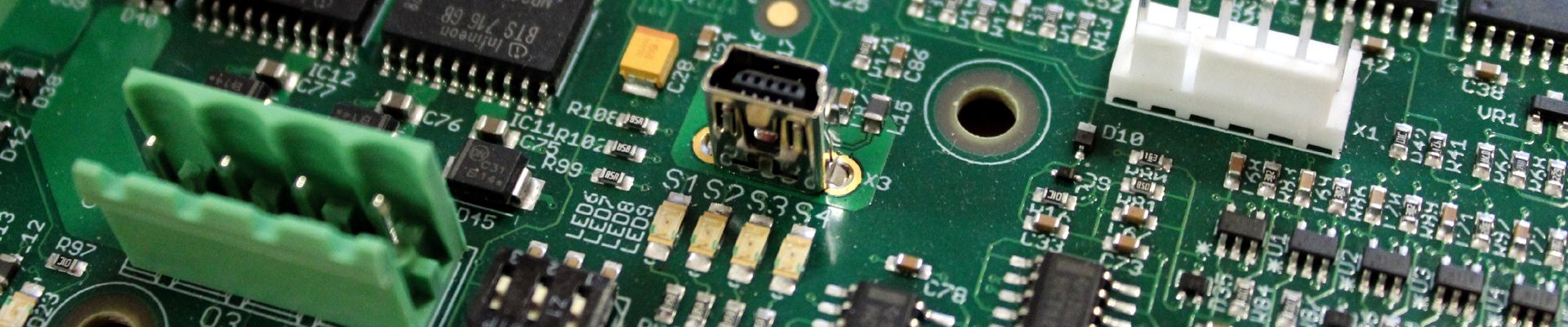

Under the brand name Tele Mast, Nijhuis Engineering Dronten BV transfer hydraulic excavators into Hi-Rail configuration to enable the machines to work both on the road as on the track. Nijhuis Engineering is unique in being one of the few in the world if not the only in the world, not only to design and manufacture the mechanical modifications in-house, but also the electronic micro processor safety devices. This makes it possible to be alert and react quickly to integrate enhancements, additions and special customer requests. In the unlikely event of a fault it can responding fast and as being it their own design. It is also possible to make a seamless link between the mechanical, hydraulic and electronic adjustments. All mechanical engineering are calculated by its own 3D CAD designers and drawn, while their own programmers and electronic engineers providing the protections.

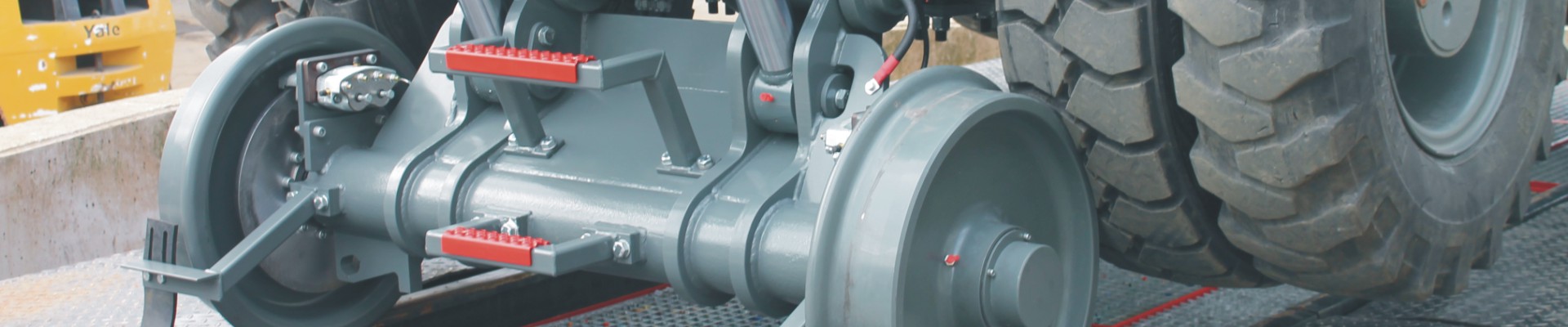

The structure may called for: "High or Low riders' or rail wheel driven versions (e.i. crawler excavators). Because Nijhuis Engineering all electronics, electrics and hydraulics are under its own management and having a very complete machine shop, the conversion to a Hi-rail can quickly be achieved at a competitive cost. The custom Hi-rail meets the EN standards and the requirements of rail infrastructure. To test the machines Nijhuis Engineering has a unique simulation test platform, in which all possible positions and loads can be implemented and results been measured.

Additional options such as: outriggers, extra lifting arms, tools, high work buckets, hydraulic brakes on the rail wheels, supervisors seat, tool boxes, tow bars, etc. are possible. Likewise special counter weight enlargement can be determined very efficiently by the unique test rig.

Specifications:

- Complete 3D CAD engineering, construction and building in-house.

- Completely according to EN 15746-1 and 2 and the requirements of rail infrastructure built.

- Fast, complete and cost-effective construction of a Hi-rail, having everything in-house.

- Flexibility in making special adjustments by our own programmers.

- Many options possible.

- Two crane operation program optional.

- Proprietary protections are customized for your machine.

- Quick change between rail and tram wheels possible.

- Failsafe hydraulic track wheel disc brakes (optional).

- Rail Set module construction can be adjusted in a very short time Total certified by European Notified Bodies (e.i., TÜV, HHC Aboma Rail etc).

.jpg)

.jpg)

.jpg)

.jpg)